Description

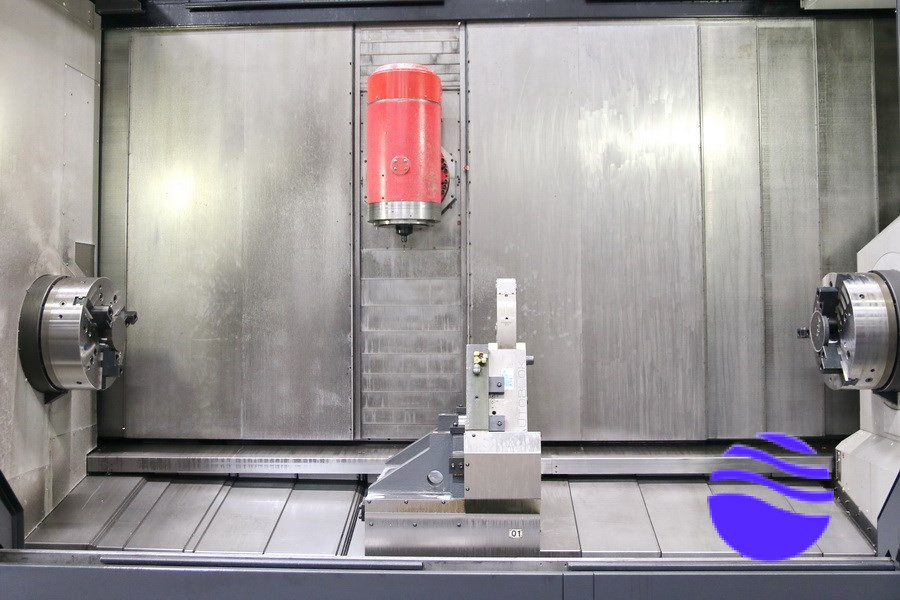

Additional information: CNC high-performance turning and milling center DMG MORI SEIKI – NT 6600 DCG / 3000 BS

Main and counter spindle

Tool spindle

2x three-jaw chuck “SCHUNK – ROTA THW 500-128”

1x steady rest “SMW AutoBLOK – SLU 6ZS 125-460″mm

Operating hours:

Power on: approx. 23,000h

Operating time: approx. 6,400h

Processing: approx. 5,000h

Technical details

Turning diameter: max. 1,070 mm

Turning length: max. 3,076 mm

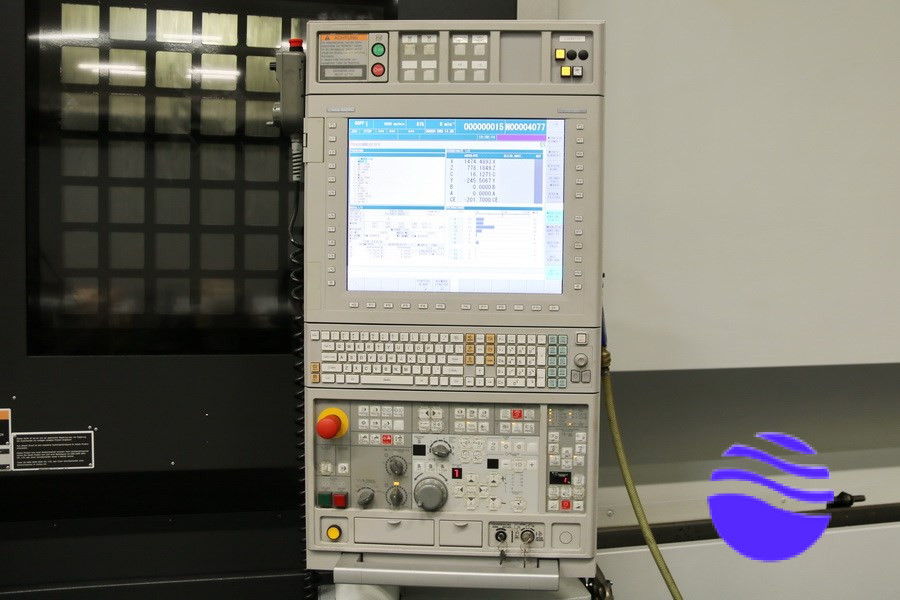

Control: Fanuc 31iB5

Max. turning diameter: 1,070 mm

Max. distance between centers: 3,510 mm

Travel distances:

x-axis: 1,040 (1,000 + 40) mm

y-axis: +/- 330 mm

z-axis: 3,150 mm

b-axis: +/- 120 °

z-axis 2: max. 2,440 mm

Main spindle:

Max. spindle speed: 1,500 min/-1

Number of speed ranges: 2

Drive power – Main spindle: 30 / 26 kW

Max. torque: 3,254 Nm

Spindle bearing diameter: 260 mm

Spindle bore: 185 mm

Max. usable bar diameter: 164 mm

C-axis: 0.0001 °

Spindle nose: JIS A2-15

Counter spindle:

Max. spindle speed: 1,500 min/-1

Number of speed ranges: 2

Drive power – Counter spindle: 30 / 26 kW

Max. torque: 3,254 Nm

Spindle bearing diameter: 260 mm

Spindle bore: 185 mm

Max. usable bar diameter: 164 mm

C-axis: 0.0001 °

Spindle nose: JIS A2-15

Tool spindle:

Max. speed: 8,000 min/-1

Drive power: 30 / 22 kW

Max. torque: 302 Nm

Tool holder: Capto C8

B-axis: 0.0001 °

Inner diameter: 100 mm

Tool magazine:

Number of tool positions: 50 pos.

Max. tool diameter: 120 mm

Max. tool diameter with free adjacent box: 250 mm

Max. tool length: 600 mm

Max. tool weight: 30.0 kg

Feeds:

Rapid traverse (X / Y / Z): 40 / 30 / 32 m/min

Rapid traverse B: 23.8 min/-1

Rapid traverse C: 70 min/-1

Feed speed: max. 40,000 mm/min

Total power requirement: 160 kVA

Machine weight approx.: 46.0 t

Space requirement approx.: 11.0 x 5.0 x 5.0 m

Accessories

Documentation

Coolant system

High-pressure cooling: 70 bar

Tailstock function counter spindle

Steady rest I/F

Steady rest SMW-SLU 6ZS (125-460)

Oil mist extraction

Chip conveyor

Automatic door

Signal lamp – triple

Tool magazine: 50 pos.

Probe: Renishaw RMP 60

Three-jaw chuck: Schunk ROTA-THW500-128

Paper band filter: KNOLL – KF 110/700

Flush gun

Direct measuring system: X, Y, Z, B

Electric handwheel

Linear interpolation tool spindle

Taper / spiral interpolation

3D model